Well-Maintained Central Plants Are a Facility’s Lifeblood

Principal Chuck Dale-Derks discusses maintenance and inspection tasks for your central plant.

I just spent $3,700 for a dealer to inspect and repair my daughter’s 8-year-old passenger minivan. The value of the vehicle is about $4,200; however, a new replacement would have set me back $27,700 (less the trade-in value). In my opinion, this is still the most economical vehicle to own and drive, and my decision to repair is a good one. I got 14 years and 404,000 miles out of my passenger minivan. Can this thought process carry-over to a facility’s central plant? Definitely, maybe.

In 2018, ASHRAE updated Standard 180, “Standard Practice for Inspection and Maintenance of Commercial Building HVAC System,” an ANSI/ASHRAE/ACCA industry standard. This is a minimum standard for new and existing buildings, and section 5 includes a list of required inspection and maintenance tasks by system or major equipment type.

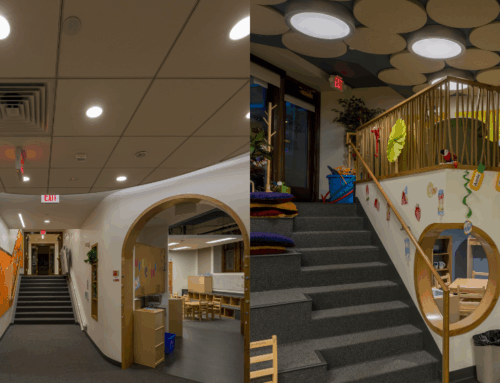

Informative appendix D to this standard lists reasons for adjusting maintenance task frequency. One reason for this is seasonal equipment operation (shutdown of a cooling tower during winter); however, this doesn’t imply that inspections are skipped during the shutdown period. Most large diameter piping systems will last throughout their intended lifespans at a high 3-5 mil per year corrosion rate. However, higher corrosion levels always present a greater opportunity for more severe operating problems to develop and narrow the margin of safety between trouble-free operation and disaster. Rust deposits produced by a 3-5 MPY corrosion rate will often initiate higher under deposit corrosion activity elsewhere and in areas less tolerant of such loss. The chemical treatment system often relies on the head pressure differential of the condenser pump to maintain flow for proper chemical injection, mixing, and monitoring.

Figure 1: Condenser water piping with chemical treatment, a freeze protection pump, and a heat exchanger.

Biocides used in the treatment of condenser water systems carry with them relatively short half-lives so that their discharge in the blowdown does not negatively affect the bacterial cultures critical to the operation of local wastewater treatment plants. However, shutdown of the condenser water flow means the chemical properties in the chiller condenser bundle may degrade and fail to protect the chiller’s tubesheet and heads from corrosion and pitting. Furthermore, corrosion in the cooling tower may also be occurring when the water flow is stopped for a long period of time. There may be flow through the cooling tower for freeze protection; however, the chemical injection and monitoring points may not be positioned to effectively maintain proper water chemistry throughout the component parts of the system — the chiller, pumps, cooling tower, and piping in between each.

Careful consideration must be given for all modes of operation and how to maintain the water chemistry. Some facilities choose to drain the condenser water system; however, this introduces ambient air and oxygen into the system that likely has small pockets of water that cannot be drained and will add to pipe and steel corrosion. The evidence of damage becomes clearly present during startup when flakes break from the interior of the piping and end up in the strainers or in the cooling tower distribution basin nozzles.

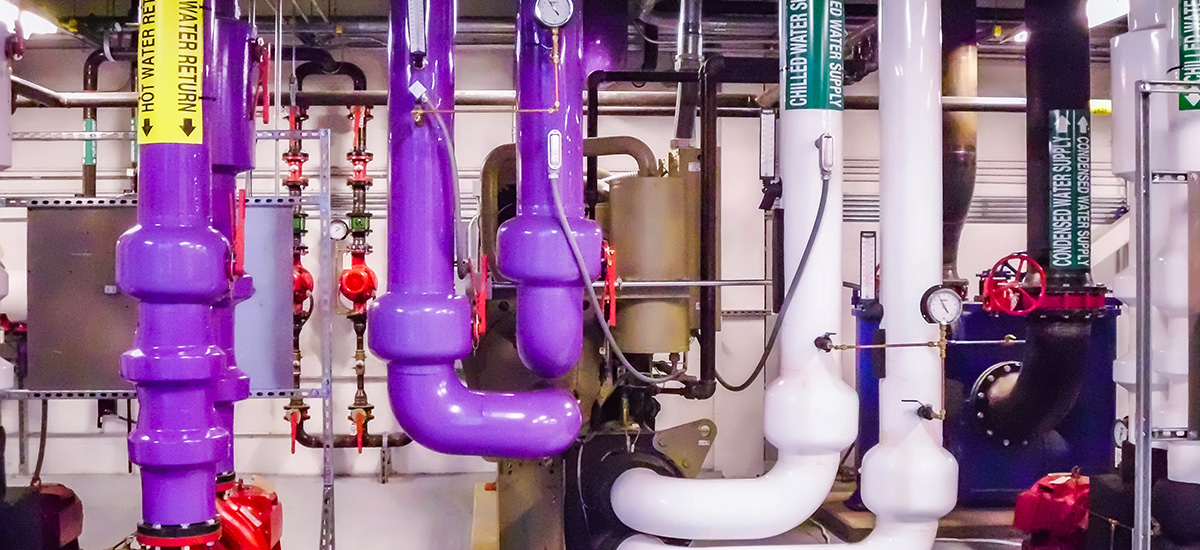

Figure 2: An inlet on the condenser water side of a heat exchanger.

Another means of protecting the chiller tubesheets and heads is to clean and coat the pieces with a polymer ceramic or epoxy coating. A nearby school district took this approach at a cost of about $11,000 for each two-chiller plant. This protection does not continue throughout the piping, nor does it protect the pumps or cooling tower. It will extend the life of the chiller and will prevent leaks at the chiller’s tubesheet.

Figure 3: An inlet of a condenser water pump with evidence of pitting and flaking.

A design option for protection of piping may be to use stainless steel piping, fiberglass piping, or high-density polyethylene thermoplastic piping.

My daughter’s minivan needed extensive repairs (new brakes and rotors) because the individuals providing the last several oil change services failed to observe the deteriorating condition of the brake pads.

If your facility uses an outside chiller service contract, are you confident in the level of service and inspection being provided? The bare minimum may include only the scheduled maintenance. This cost may be about $3,000 per chiller and may include four service visits per year per chiller. McClure Engineering recommends this service. In comparison, the cost to only replace the oil for a chiller may be about $1,500 for a single service call in one year.

A step above the minimum scheduled maintenance-type service is to perform a 10-year overhaul of the chiller. The overhaul may cost about $70,000 per chiller, which may be about 50% of the price of a new chiller (materials only).

Figure 4: Chat under the drive coupling indicates a misalignment or a potential of cogging caused by the VSD carrier frequency being too low and the pump running at too slow of a speed.

A third level of “service” may include extended equipment warranties, offering a temporary chiller if one should fail and a budget level fee for extended periods, which includes regular scheduled maintenance and overhauls on the 10-year equipment cycle. School districts may favor this type of level financed expenditure to avoid the awkward board meetings and annual ask for maintenance funds.

Other component service repair costs have included about $8,000 for a warped economizer flange, approximately $7,000 for a tang operator, around $5,000 for an oil pump replacement, nearly $10,000 for a control panel upgrade or replacement, and approximately $7,000 for a purge unit replacement. Why do we always have an emergency repair? Because we don’t include money in the budget for servicing the equipment.

What should a district budget for emergency repairs?

In my opinion, if the chiller efficiency is good, and especially if it is a low-pressure centrifugal machine, it’s worth the expense to repair and extend its service life.

Figure 5: An over-greased fluid cooler fan bearing.

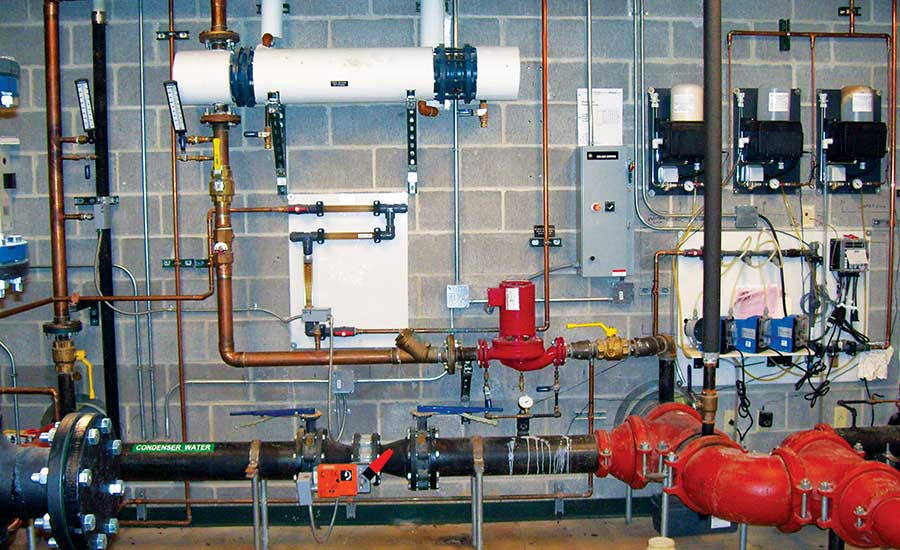

The chiller and condenser water pumps can be an easier task to inspect and maintain because they are fairly simple devices; however, these can be more complicated to understand on variable flow systems. Standard 180 suggests an annual check of the flow, an annual cleaning of the strainer, and a semiannual check of the drive or starter. Checking the pump (and every central plant piece of equipment) should start with listening to the unit operate. Is the speed hunting? Does it sound like there’s gravel in the pipes? Is there a vibration or high-pitch sound emanating from part of the assembly?

Also, a fluid cooler or cooling tower is a relatively low-complexity piece of equipment; however, there are significant differences in styles that require different inspection and maintenance tasks or frequencies. Fan shafts installed in the vertical orientation require lubrication at twice the frequency as horizontally mounted shafts. Vertical shaft bearings should be lubricated (greased) every three months. Marine synthetic grease with lithium thickener is usually recommended. How many types of grease does your facility maintenance staff carry or have access to? Also, if the cooling tower is shut down for the winter, is the shaft hand rotated monthly to keep motion in the bearing and prevent flat spots on pressure or weight points? Extended lube lines may be convenient but may also allow service without visually inspecting the bearing. Over-greasing a bearing can cause damage by attracting dirt and debris, which can work its way into the bearing and cause damage.

Figure 6: A dirty air-measuring station will produce an error affecting building pressurization and/or ventilation rates for the occupants.

Moving to air-side equipment, these components are important to the indoor comfort and wellbeing of the occupants. They can be complicated and of many different configurations. Sub-components may include filters, an energy recovery component, a preheat coil, a cooling coil, a reheat coil, a supply fan, control dampers, an economizer, an exhaust fan, control valves, VSDs, and other parts. A picture diagram is often necessary to understand how they operate. If the unit has a fan wall with multiple direct-drive fans, it’s imperative that the design flow fan speed be clearly marked on the unit. 60 Hz is no longer necessarily the fan full speed at design conditions. A thorough understanding of each air system is necessary to develop a proper and complete inspection and maintenance task list.

Inspection and maintenance of your central plant is imperative to keeping it operating and significantly reducing, if not eliminating, emergency repairs. Well-maintained central plants are the lifeblood of the facility. Care and attention to inspection tasks, even during offseasons, will keep your equipment in top shape. I recommend every maintenance department have a copy and understanding of ANSI/ASHRAE/ACCA Standard 180-2018, “Standard Practice for Inspection and Maintenance of Commercial Building HVAC System,” and have a thorough maintenance plan.

Chuck Dale-Derks, P.E.

Published July 17, 2019 in Engineered Systems

Chuck Dale-Derks, P.E., is a principal at McClure Engineering, a mechanical and electrical consulting engineering firm dedicated to the development of innovative solutions to unique engineering problems.