East Wing AHU Replacement

Saint Louis Art Museum

Project Background

The Saint Louis Art Museum (SLAM) is one of the principal art museums in the United States, housing paintings, sculptures, cultural objects, and ancient masterpieces from all corners of the world. The original three-story building has stood in Forest Park in St. Louis, Missouri since 1904, constructed as part of the World’s Fair. With a total floor area of 125,000 sq. ft., the original building consists of The East Wing, The West Wing, and Sculpture Hall – a vast atrium at the junction of the two. Numerous other building sections have since been added to the facility.

Previously, HVAC conditioning for the East Wing of the museum was provided by a pair of 50,000 CFM indoor air handling units (AHUs), with one serving the north-most galleries of that wing, and the other serving the southern ones. During the recent replacement of those mechanical units, this division of gallery service was generally maintained. However, instead of a single AHU serving each half of the East Wing, McClure Engineering’s design utilized a pair of units: one AHU and one makeup air unit (MAU) per half.

Project Deliverables

Energy Efficiency

The prior generation of AHUs serving the East Wing of the museum were standard mixed-air units, with the outdoor air and return air streams mixing prior to entering the units. Because of this configuration, the units had to cool the entire airstream to sufficiently dehumidify the air prior to sending it to the spaces. The byproduct of this is that the same airstream then also required a significant amount of reheat in order to avoid sub-cooling the galleries.

In an effort to reduce energy consumption, the McClure Engineering team replaced the old AHUs with a new, more efficient unit configuration. Specifically, by adding MAUs upstream of the new AHUs, it allowed for independent conditioning of the outdoor and return air streams. Through this arrangement, the outdoor air could be over-dried to the point that the return air stream did not require any dehumidification. This, in turn, allowed the return air to only be cooled as much as required to maintain space temperature. By optimizing the cooling and reheating processes, the new AHUs achieved significant energy savings while still meeting the strict temperature and humidity requirements of the galleries.

Innovation

While energy reduction was a major impetus of the project, it was not the aspect of the project that required the most attention. Instead, the most challenging aspect of the project was the physical space in the mechanical room, combined with the scheduling and phasing of the new unit install.

Even prior to the new units, the mechanical room was tight. In order to fit four units into the space where two units previously resided required notable space conservation. A sizeable part of this was gained by changing from a single, centrifugal fan to an array of much smaller plenum fans. This also allowed for the elimination of the fan evase, decreasing the new AHU length by more than 10’. Additionally, air coming from the MAUs were configured to bypass the filters and cooling coil in the main AHUs, allowing for the new AHU cross-sectional area to be reduced significantly from the previous AHUs.

Beyond physical layout, a significant amount of the design effort involved planning for phasing of the unit replacement. Because the previous AHUs served largely non-overlapping areas, and the galleries remained active at all times during the construction, the AHUs had to be replaced non-simultaneously. Moreover, supply and return air ductwork from the downed unit needed to still be provided air from the operating one in order to maintain gallery temperature and relative humidity setpoints. This was achieved through the use of manually-operated crossover ducts, along with some additional temporary ductwork. When one of the units was down, the crossover ducts could be opened, and the operating unit would serve the entire East Wing.

Not only did these crossover ducts provide use during construction, but they were left in place afterward to provide redundancy for the new units. Specifically, it allows full space conditioning to be provided for most of the hours of the year if any one unit fails.

Indoor Air Quality

While the previous AHUs originally had the capacity to bring in outdoor air, the museum had closed off the outdoor air dampers for the past few years due to difficulties maintaining winter relative humidity setpoints during the coldest weather. As part of the AHU replacement project, the team at McClure Engineering was able to re-introduce outdoor air to the East Wing.

Another improvement the design team made in terms of building air quality was through improving the museum’s filters. Previously, the museum had been using MERV 13 filters in the East Wing AHUs. As part of the overhaul, the team upgraded the filters to a high-capacity MERV 14 filter. Despite capturing small particulates more efficiently than the prior filters, the new filters still had a lower pressure drop than the previous generation due to designing around a deeper filter.

Environmental Impact

The largest environmental impact resulting from the project was reduction of energy consumption in the museum wing. By eliminating the unnecessary reheat of air, the museum was able to substantially reduce its carbon footprint.

Operation & Maintenance

A number of improvements to operations and maintenance were incorporated into the design of the AHU replacement project. The first of these was simply access into the mechanical room itself. Located within the sub-basement of the museum, the mechanical room access was limited to a single 3’ wide door through a 20” thick concrete and brick wall, after which the users had to immediately descend down a steep ships ladder. As part of this project, the door was expanded into a double door, and the ships ladder was replaced with a full landing and standard stairs. Moreover, a motor hoist beam assembly, rated for 1200 lbs., was installed at the landing to allow for easy replacement of failed motors and other parts within the mechanical room.

Within the AHUs themselves, an array of smaller plenum fans was a welcome contrast to the single, large centrifugal fan that moved air in the previous generation of AHUs. The new fan array added redundancy to the system and, being significantly smaller than the previous fan, allows for easier and faster replacement of the fans and motors.

Maintenance improvements also extended to other portions of the mechanical room as well, namely the zone terminal units. Under a 2017 project, built-up VAV boxes were added to the East Wing AHU supply ductwork within the mechanical room as part of a conversion from constant speed to variable speed. Due to the severely limited free space at the time, as well as routings of the existing supply ductwork, many of the VAV boxes were located above the AHUs and other non-ideal spots. Consequently, they have been difficult to access by maintenance since that install, with some boxes requiring crawling across the top of the AHUs. Under the AHU replacement project, the VAV boxes were not moved or replaced, but the new AHUs and ductwork layout allows maintenance to walk across the top of the AHUs to access these same boxes. Furthermore, there is space at the VAV boxes themselves to replace the coils/valves/etc.

Cost Effectiveness

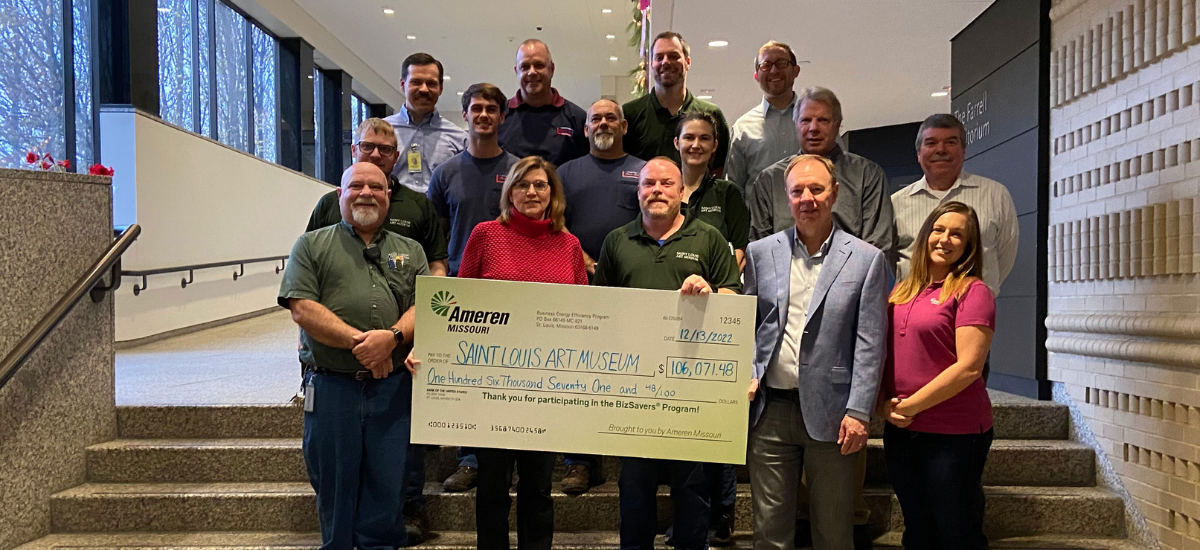

Through McClure Engineering’s efforts, the St. Louis Art Museum received more than $100,000 in cash rebates from Ameren Missouri’s Biz Savers Program for the replacement of the two AHUs. This amount well exceeded the original estimates of $45,000 and $75,000 and was welcomed by the owner.

PROJECT DETAILS

Architect Of Record

N/A

Construction Cost

Confidential

SQ. FT.

125,000

Market Sector

Cultural Institutions

Year Completed

2022

LEED

N/A

Our Services

Principal

Keith Esarey, P.E.