Maintaining Proper Pressure Cascades Are Crucial to Contain Laboratory Contaminants

Principal Erik Eaves discusses maintaining proper pressure cascades which are crucial to containing contaminants.

Biosafety Level 3 (BSL-3) space pressurization is critical to reducing the potential spread of infectious diseases in laboratories. HVAC systems serving spaces with this classification should be designed with a higher level of airflow control than those serving general laboratories. The following topics must be considered to ensure the successful design and installation of a BSL-3 laboratory.

Importance of Pressure Cascades

Developing a proper pressure cascade is imperative for BSL-3 laboratories. Pressure cascades minimize the potential for diseases or contaminants to spread to other parts of the building that are not classified as BSL-3 spaces (i.e. corridors, offices, general laboratories).

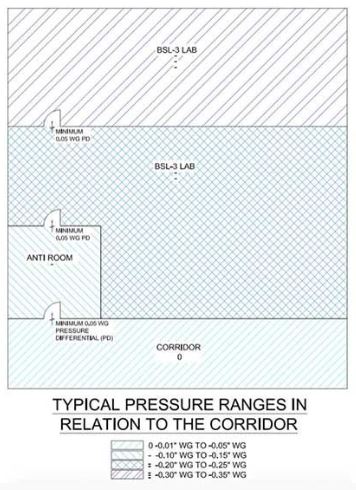

The BSL-3 laboratory suite is typically isolated from the building with an airlock (anteroom) that all laboratory personnel must pass through to enter. Air pressure will then progressively decrease until entering the “deepest” (farthest cascade) part of the BSL-3. To minimize risk, the cascade layout should start with the lowest risk labs and progress to the highest risk labs. Many designers will place a pressure sensor in the corridor adjacent to the lab area, design the pressure in the airlock to be negative relative to the pressure in the corridor, and design the actual laboratory to be negative to the airlock. Thus, a cascade effect is developed beginning in the corridor and ending within the BSL-3 lab. See Figure 1 for a typical cascade example.

While it’s typical for a designer to place the pressure sensor in the corridor where the lab suite’s pressure differential is based (i.e. corridor differential to the airlock), there are several important factors to be considered. The air pressure in the corridor should not be positive relative to the rest of the building or to the atmosphere. Keeping the corridor neutral to slightly negative is preferred. This will reduce the likelihood of airborne diseases spreading outdoors or to adjacent non-BSL-3 spaces.

Many of today’s buildings fluctuate in pressurization between internal spaces and to the atmosphere on a daily basis. Much of this fluctuation is due to VAV systems and economizers. Many buildings that house BSL-3s have these types of systems for offices, conference rooms, and other non-lab spaces. These pressure changes in the other portions of the building can be important to the BSL-3 design. The lab space should always be negative to the remaining building. To help relieve some issues that could develop due to changing pressures throughout the building, the design should ensure that the corridor where the base pressure is tested and general space adjacent to the corridor are maintained at a consistent pressure.

Figure 1: This diagram displays a BSL-3’s typical pressure ranges in relation to the corridor.

Typical Problems with Space Pressurization

Let’s assume the BSL-3 lab has been designed and installed with all of the systems and components necessary for proper operation. Now, it’s time for the systems to be balanced, so the users can move and start their work. The testing and balancing contractor arrives and finds that he or she is unable to balance the system per the design. There are some usual suspects that should be reviewed when balancing difficulties arise.

Leaks in the laboratory are the biggest cause of why these spaces can be difficult to balance. The entire room should be sealed to help minimize leakage. Door sweeps should be installed on all doors leading to the airlocks and in the laboratory. Gaps at the bottom of the door can be utilized if unidirectional airflow is desired. It’s not a bad idea to install door sweeps in the corridor serving the BSL-3 laboratories. Also, the doors should be self-closing. If the door does not self-close, the pressure cascade will not operate properly.

On occasion, there have been instances of air leaks from the door frame itself caused by a considerable amount of air passing through the door lock holes. The door frames should be made airtight internally and to the adjacent spaces.

There should not be any gaps from the pipe penetration through the wall for air to pass. All penetrations in the BSL-3 should be sealed, including conduit, piping, and ductwork. To help with the balancing of the HVAC systems to produce pressurization, the floor should be seamless, welded, vinyl flooring, and the light fixtures should be recessed and gasketed. In addition to the light fixtures, all other devices in the ceiling should be gasketed (tight construction) to reduce the leakage concern. The intent is to tighten the space as much as possible and allow unidirectional flow under doors when desired or needed.

Room Cascades Pressure Differentials

Typical BSL-3 design requires a minimum of 0.05 wg pressure differential for each cascade. Many HVAC systems are designed to alarm at this minimum value. To allow variance in the spaces without triggering alarms, the differential pressure for each single cascade should be designed closer to 0.1 inch wg with differentials typically no greater than 0.2 inch wg. Overall, all spaces within the suite will be negative to the adjacent non-BSL-3 corridor.

How HVAC Controls/Balancing are Important for Improved Pressure Cascades

Laboratory controls should be quick acting, as pressures can change rapidly in BSL-3 labs that have variable flow fume hoods. As the fume hood sash closes, there is less exhaust through the hood and more diverted to the room exhaust. The valve boxes and controls must react quickly for the lab to maintain its required pressure. Venturi-style air valves typically work well in this application.

When balancing a system, the balancer should balance the BSL-3 room to the exhaust values listed first and then balance the supply air. Supply air quantities must be balanced to achieve the required pressure range. Some of the difference in the airflows between the supply and exhaust are captured in the room leakage. The tighter the room is constructed, the easier the system will balance. If the space has significant leaks, the supply air will have to be backed off a considerable amount. If the leakage is too great, even closing off the supply completely may not produce the required negative pressurization. And of course, the supply cannot be completely closed off as it needs to meet ASHRAE 62 minimum requirements for ventilation. The typical starting point for exhaust air is about 15 percent greater than supply air to achieve the required negative pressure. As needed, most designers will typically leave an air gap under the door for unidirectional flow.

In conclusion, space pressurization is critical to the successful design and installation of BSL-3 laboratories. Considering additional containment measures will help reduce the likelihood of spreading disease outside the lab and into other parts of the building.

Erik Eaves, P.E.

Published November 21, 2018 in Engineered Systems Magazine

Erik Eaves, P.E., is a principal at McClure Engineering, a mechanical and electrical consulting engineering firm dedicated to the development of innovative solutions to unique engineering problems.