Campus Geothermal Energy System

Missouri University of Science & Technology – Rolla, Missouri

Project Background

A Level III campus energy study was conducted by McClure Engineering for the entire campus of Missouri University of Science and Technology in Rolla. It was completed in 2010 which lead to a massive geothermal and campus utility project completed in 2014. The energy study included building walk-throughs, bill analysis, measured data, cooling energy models, heating energy models, and carbon footprint calculations. Telcom infrastructure and water savings were also considered and incorporated into the overall design. Early Energy Conservation Measure (ECM) packages were released in January and July of 2010 to enable work to start right away to capture savings and incentives as soon as possible. A total of 25 ECM’s were presented with associated cost opinions and paybacks. The study covered approximately 1,692,000 square feet of buildings with distributed steam and 837,000 square foot of dedicated gas or electric heating systems. Missouri S&T does use interruptible natural gas which was taken into account for several buildings with regard to payback and heating plant design.

Project Deliverables

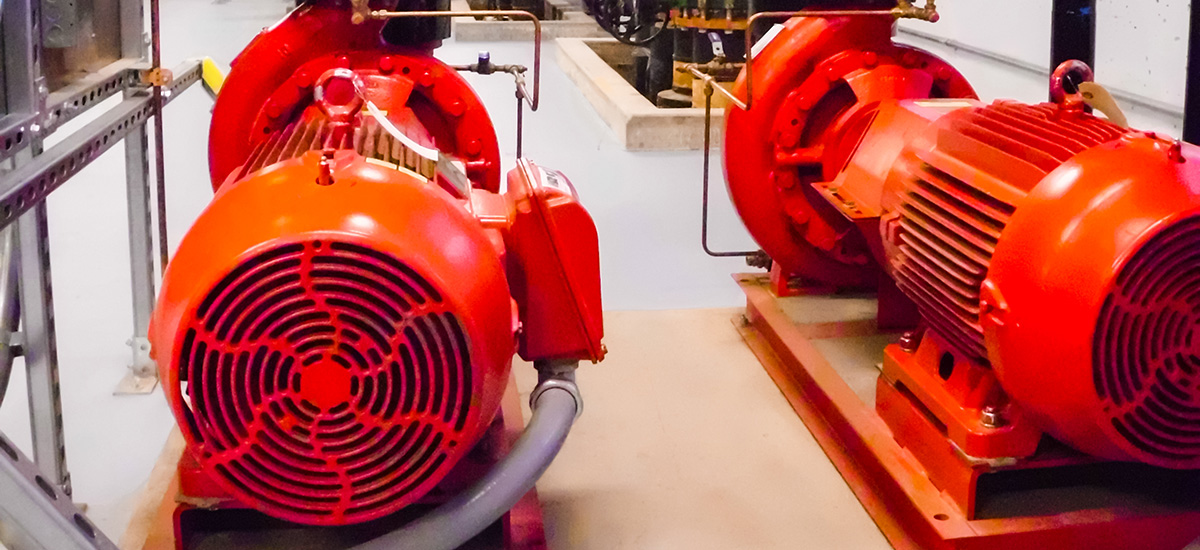

The $30 Million construction project provides heating and cooling to 16 campus buildings and replaces the existing coal-fired steam plant serving the whole campus. This system is designed to accommodate future expansion per the University’s master plan. The system saves more than $1M in energy and water costs annually. The system includes 645 vertical bore wells, 420 to 450 feet deep, combined into closed loops serving the three campus geothermal plants. Each of the three plants contains 500 Tons of heat recovery chillers, peak well heat rejection load shaving cooling towers, and peak well heat extraction load shaving gas-fired boilers to provide geothermal source based chilled water and heating water to buildings on the campus. The hybrid geothermal plant design has been optimized based on a life cycle cost analysis, energy usage, and incentives. The project includes the integration of the new chilled water distribution system from the plants with the existing seven electric chiller plants for an automatically sequenced campus-wide 2-pipe chilled water control system. The heating water distribution system from the plants is also 2-pipe and consists of two shared heating plants and one standalone heating plant. Additionally, the buildings were retrofitted for low temperature heating water instead of steam heating and de-coupled building chilled water and heating water distribution systems. A third medium voltage power loop was created so each geo plant was on a separate medium voltage loop. Empty conduit and junction boxes were provided for a future upgrade to the campus data network.

Challenges

The energy study conducted by McClure Engineering included natural gas heating as well as conventional electric and heat recovery chiller options as well as the geothermal option. McClure Engineering utilized the energy study to evaluate each building as well as the overall campus’ heating and cooling needs, as well as their desire for energy efficiency, minimal carbon footprint, and reduced energy costs. To find the best solution, McClure created an hour-by-hour energy model of the campus and modeled various options. The model was compared to metered data to verify its accuracy. The ground source heat pump system was chosen for its ability to store rejected heat in the ground during the summer and use that heat for building heating during the winter. A unique feature of this design was the decision to utilize a hybrid system (with gas-fired boilers and existing electric chillers to shave the peak loads), which greatly reduced the number of wells required, enabled the project to fit within the University’s budget, and provided redundancy in both the heating and cooling systems.

The project includes removing the old steam system and connecting 15 campus buildings to a distributed district heating system. The challenge was the conversion of all of the existing buildings to the new heating system (a low temperature, 120-degree system) as they were originally designed with other operating parameters. Because each building is unique, McClure examined them individually (on paper and on-site) to determine the optimal ways to make the systems all work together. In many cases, the best solution was to replace equipment in the buildings to work with the new, low temperature heating system. This allowed the design to maintain high water temperature differentials, thus keeping flows and pump horsepower to a minimum in the buildings and plants. In a few buildings, confirmed via empirical measurements, the existing coils were reused since they were originally oversized during design. A steam boiler was placed in one building to maintain lab serialization, humidification, and the existing steam heating system.

McClure phased the construction of the entire project which included work in existing buildings, construction of new heating/cooling plants, and miles of geothermal piping. Complications included coordinating the work of several subcontractors, minimizing the disruptions to the campus and building occupants, weather delays, and keeping as much of the campus with heating and cooling as possible while installations are completed.

Lesson Learned

After the project was completed the water saving was much greater than McClure estimated. The cooling tower evaporation was significant (10,000,000 gallons) but the undetected leaks in the water mains (8,730,000 gallons) were as well. As part of the project, several older mains were replaced or bypassed with new HDPE water mains as a successful effort to differ future maintenance costs.

PROJECT DETAILS

Architect Of Record

N/A

Construction Cost

$30,000,000

SQ. FT.

1,692,000

Market Sector

College & University

Year Completed

2015

LEED

N/A

Our Services

Principal

Phil Wentz, P.E.