Mixing Valves Play a Key Role in Water Safety

Thermal disinfection is the safest, most cost-effective method for controlling bacteria within plumbing systems.

Legionella is an important topic that has been brought to the forefront of water safety discussions in recent years. Legionella is bacteria that is naturally present at low levels in freshwater environments but becomes a problem when water droplets containing the bacteria are inhaled. This can lead to a severe form of pneumonia called Legionnaire’s disease that can be fatal for those with compromised immune systems.

To combat Legionnaire’s disease, exposure to the bacteria must be reduced. For building occupants, this means targeting the bacteria living within the plumbing system. Methods used to control the bacteria include chemical disinfecting, mechanical filtration and thermal disinfecting. Of these methods, the safest and most cost-effective option is often thermal disinfecting, which involves heating the water to a degree that kills the Legionella bacteria.

Figure 1: To combat Legionnaire’s disease, exposure to the bacteria must be reduced. For building occupants, this means targeting the bacteria living within the plumbing system. Image source: Maridav / Shutterstock

Legionella bacteria’s ideal growth range is between about 83° F and 113° F. Below that temperature range, Legionella can survive, but growth is slowed and eventually halted as temperatures decrease. In temperatures below 68° F, Legionella is dormant. Conversely, above about 122° F, Legionella can survive, but multiplication halts. At 131° F, Legionella is killed within five to six hours. At 140° F, Legionella is killed within 32 minutes. At 151° F, Legionella is killed within two minutes, and at 158° F, Legionella is killed instantly. The higher the water temperature, the shorter the amount of time it takes to kill the bacteria. However, the higher the water temperature, the shorter amount of time it takes for a severe skin burn to occur. For example, at 140°F, a typical adult will suffer third-degree burns after six seconds, whereas at 150° F, third-degree burns occur after only two seconds. Experience shows that heating and, subsequently, storing domestic water at a temperature of 140° F is optimal. At a temperature of 140° F, the water is hot enough to kill Legionella bacteria in a reasonable amount of time but not so hot as to cause instant burn injury in the event that contact with skin occurs.

Figure 2: The IPC requires the water provided to public hand washing facilities to be between 85° F and 110° F. To lower the water temperature to be within this range, point-of-use mixing valves must be utilized at the locations where colder water is required and/or desired. Image source: Novac Vitali / Shutterstock

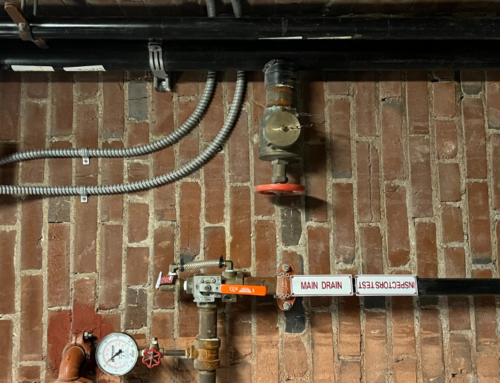

The water temperature must be lowered from the generation and storage temperature prior to distribution and discharge at the plumbing fixtures to mitigate burn risk to the building occupants. Plumbing codes have maximum water temperature requirements depending on the specific plumbing fixture to which the water is being distributed. For example, The International Plumbing Code (IPC) requires that water at individual shower valves, multiple (gang) showers and bathtubs must be at or below 120° F, whereas public hand-washing facilities require water to be between 85° F and 110° F. Mixing valves are utilized to reduce the water temperature from the generation and storage temperature down to acceptable levels prior to distribution and discharge at the fixture.

As the name suggests, mixing valves blend hot water with cold water to achieve a desired temperature using a mechanically or digitally controlled element. The master mixing valve is installed at the hot water source and ultimately sets the water distribution temperature. Per IPC 2021, section 613.1, “Temperature-actuated mixing valves, which are installed to reduce water temperatures to defined limits, shall comply with ASSE 1017 [American Society of Sanitation Engineers]. Such valves shall be installed at the hot water source.” A hot water distribution temperature of 120° F is common, with hot water recirculation designed to maintain temperatures above the ideal growth range of legionella bacteria — greater than 113° F.

Figure 3: The temperature of a building’s domestic water — from generation to storage to distribution and final outlet temperature — plays a critical role in water safety, and mixing valves are an essential piece of the puzzle. Image source: nikkytok / Shutterstock

The master mixing valve at the hot water source takes care of the need to cool the water down from 140° F to a distribution temperature of 120° F, but the temperature requirements at fixtures such as public handwashing facilities are still not met. As mentioned, IPC requires the water provided to public hand washing facilities to be between 85° F and 110° F. To lower the water temperature to be within this range, point-of-use mixing valves must be utilized at the locations where colder water is required and/or desired. IPC 2021, section 419.5 states, “Tempered water shall be delivered from lavatories and group wash fixtures located in public toilet facilities provided for customers, patrons and visitors. Tempered water shall be delivered through an approved water-temperature limiting device that conforms to ASSE 1070.”

Similarly, there are plumbing code requirements for ASSE-rated temperature-limiting devices at other plumbing fixtures. The IPC requires mixing valves at showers and combination tub-showers to meet ASSE 1016, mixing valves at emergency fixtures to meet ASSE 1071 and mixing valves in shower rooms to meet ASSE 1069. Regardless of the specific standard and plumbing fixture, the goal is to prevent scalding and thermal shock to the end user.

There is also the question of using a digital master mixing valve or a mechanical master mixing valve. As with most options, there are pros and cons. The biggest drawback to using a digital master mixing valve is the cost. However, digital mixing valves provide a much tighter control and deviation from the distribution temperature setpoint. Additionally, digital mixing valves are capable of closing their inlet ports 100%, preventing unwanted hot water temperature creep during periods of low or no hot water use; if the recirculated hot water starts to rise above the setpoint, the digital valve can close the hot inlet completely. Digital mixing valves are also typically more stable in the presence of hard water because their motors can generate sufficient force to overcome friction from scale formation. Thus, they may be more suitable for use where hard water is of concern.

The temperature of a building’s domestic water — from generation to storage to distribution and final outlet temperature — plays a critical role in water safety, and mixing valves are an essential piece of the puzzle. Mixing valves allow for the high temperatures required for thermal disinfecting, while also protecting the occupants from scalding. Mixing valves are key to a safe and successful water distribution system.

Sarah Scolari, P.E.

Published May 16, 2024 in PM Engineer

Sarah Scolari PE, CPD, received her professional engineering license in 2013 and is certified in pluming design. She is a mechanical engineer at McClure Engineering, a mechanical and electrical consulting engineering firm dedicated to the development of innovative solutions to unique engineering problems.